Franklin County Technical School seniors get to try underwater welding

| Published: 04-01-2025 3:56 PM |

TURNERS FALLS — Two Franklin County Technical School seniors recently took a deep dive into their underwater welding education.

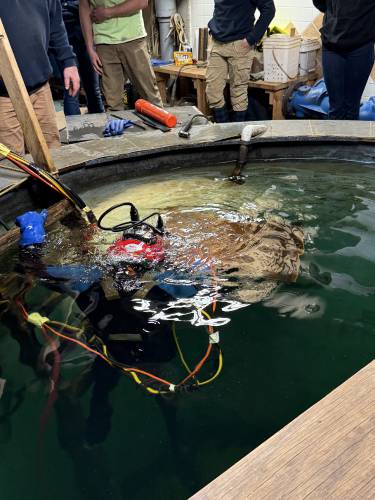

The students in the Welding & Metal Fabrication program, Collin Eddy of Leverett and Christian Hurd of Greenfield, took the rare opportunity to get a feel for what commercial divers — those trained and certified to work in construction and operational jobs performing underwater work — do as part of their careers by practicing their skills in a 12-foot-deep tank at the North Atlantic States Carpenters Training Fund facility in Millbury on March 19.

“We’ve gone there for several years, and they have a dive tank that they use to train union members to become underwater welders,” Franklin Tech welding instructor John Passiglia said of the visit to the Millbury facility.

According to the U.S. Bureau of Labor Statistics, 2,790 people were employed as commercial divers in the United States in 2023, with a median yearly salary of $61,300. The American Welding Society website explains underwater welding jobs can be found in the transportation, industrial and infrastructure industries, including positions in offshore drilling and shipbuilding.

This is the third year Franklin Tech has sent students to the training facility, and welding instructor Lorin Burrows explained this opportunity comes from reaching out to Ziven Drake, assistant executive director of the North Atlantic States Carpenters Training Fund. Drake helped the school coordinate a visit to the facility, where the students attended a monthly North Atlantic States Carpenters Union meeting ahead of the dive and got into the tank to practice some welding.

“It’s a pretty cool day,” Burrows said. “Couple of these guys have never even scuba dove.”

Burrows noted the two students acted as each other’s tenders, the term for the person who oversees or sets up the necessary welding tools for the welder. In this case, the two communicated throughout each other’s dive, with the person out of the tank watching a monitor and making sure to check in on the progress of the welding activity.

Eddy, the first of the two seniors in the dive tank, said the initial challenge was getting in the wetsuit and getting used to wearing the helmet.

Article continues after...

Yesterday's Most Read Articles

“Getting the helmet on was pretty much the first step of getting into the tank, and probably the most difficult. The helmet weighs 30 pounds,” Eddy recalled.

Eddy explained that this helmet is multi-purpose, with cameras and flashlights, along with a shaded lens for welding. He said the dive took him 20 minutes, with the first 10 spent floating in the tank and gathering tools, and the rest of the time spent welding. The helmet allows for communication between the instructors outside the tank and the diver via a speaker, Burrows explained.

“It was kind of fun to float around under the water,” Eddy said, “but the welding side of it was definitely a bit interesting. You’re trying to float around and you’re trying to weld at the same time.”

Hurd had a similar experience, though he had to strap weights to his feet to counter the buoyancy of the tank, even with the weight of the helmet. Once he was in the tank, he said the welding equipment was preset by Eddy, and the experience was worth it.

“It was something you really can’t beat,” Hurd said. “Most people really don’t even get the opportunity to weld in the regular atmosphere, let alone in the water.”

Although Burrows had some concern about the students coming into the dive without experience, he said it did not deter either of them and they both exhibited professional attitudes.

“I knew these two guys could handle it,” Burrows said. [Christian is] going to the Marine Corps, he’s got that go-getter attitude, and the other student Collin, since he was a freshman, he’s never shied away from a challenge or anything.”

Erin-Leigh Hoffman can be reached at ehoffman@recorder.com or 413-930-4231.

‘Devastating’: Cuts to public broadcasting will be felt here, local experts say

‘Devastating’: Cuts to public broadcasting will be felt here, local experts say Ahead of renovations, Memorial Hall Association invites residents to take a seat from historic theater

Ahead of renovations, Memorial Hall Association invites residents to take a seat from historic theater Customer demand drives expansion of Flis Market’s pizza offerings

Customer demand drives expansion of Flis Market’s pizza offerings Protesters to state officials: Change clean energy siting rules in new Climate Action Plan

Protesters to state officials: Change clean energy siting rules in new Climate Action Plan